How to ensure longer using life for hot air application

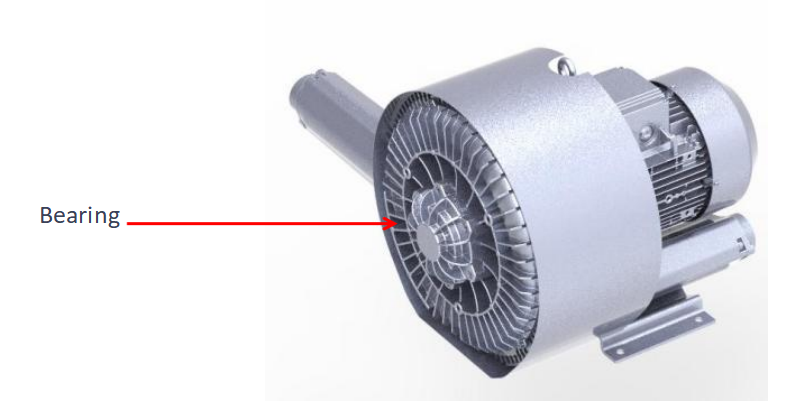

Some blowers fail due to long time hot air operation . After disassembling the blower ,you may find the problem caused by bearing failure .

How to solve this problem ?

1. Replace the bearing with SKF MT or GJN grease high temperature resistance bearings .

High temp. Resistance up to 180 degree .

2. Replace the blower with our high temp. Resistance Type blowers .

The principle is to move the bearing to an individual space from the casing inside ,so that that

The bearing grease can be highly protected and durable .

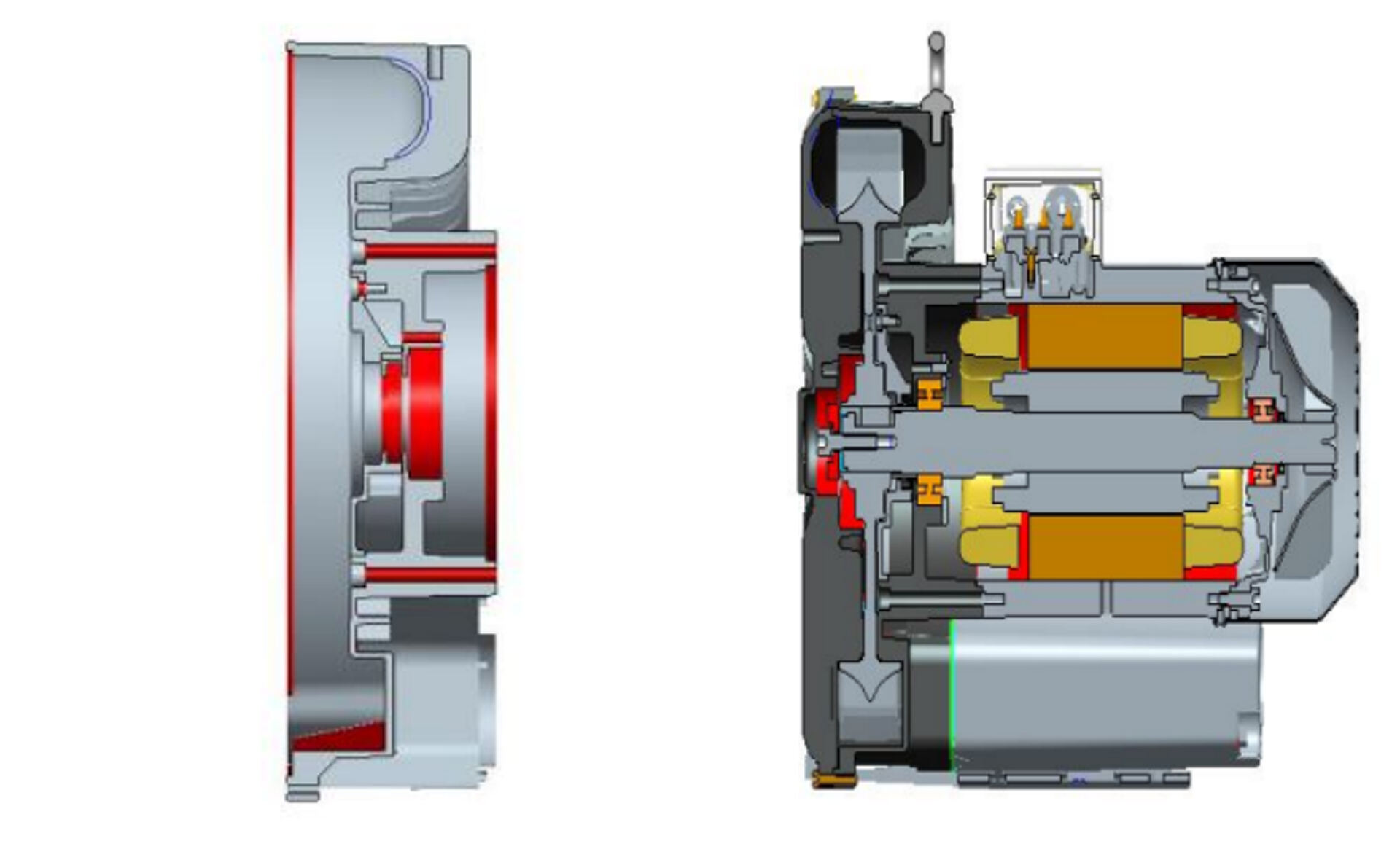

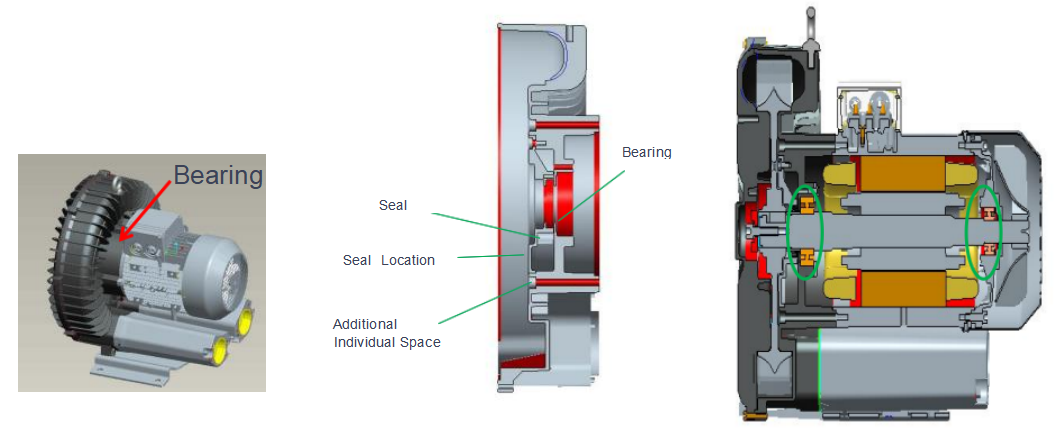

Detail plan shows below :

Single stage blower solution

Instruction :Bearing which ever located inside of the casing has been moved to an additional individual space by mould.and seal by a rubber seal .

Advantages :

a.Bearing will not be affected by the hot temperature as well as small article or dust or corrosive gas inside of the casing ,highly improved the using life .

b. Bearing is put separately ,temperature of it is always cool as well as Bearing Grease , highly improved bearing using life

c. Bearing failure is the most common failure to a blower ,The bearing can be fully protected , the complete blower using life could be much longer .

d. This kind of design is suitable for the special application such as a little dust ,corrosive gas , high temperature and so on .

Double stage Blower Solution

Double Stage front bearing type is not only with the complete advantage for single stage blowers but also the bearing can be discharged easily by discharge the outside small cover without disassembling the complete blower.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

AF

AF